There are many reasons for this including the fact that Boxer is more common in the US making it more accessible to American reloaders. Corrosion allowances are normally established by the end user and are somewhat based on personal preferences and industry tradition.

Portions of the steel casing appear to ha.

. Hi everyone new to the forum. Casing grades mainly differ in their yield strength tensile strength and hardness. Material sele ction for setting the casing an d equipping wells with aggressive gases should be given.

This video shows extreme steel casing corrosion in a former public water well in Rockbridge County Virginia USA. The cost of casing is a major part of the overall well cost so the selection of casing size grade connectors and setting depth is a primary engineering and economic consideration. For more details refer to NACE MR 0175ISO 15156.

A review of the different types of corrosion is often helpful in initially determining the likely corrosion cause. A commonly used grade for most wells when it meets the design criteria. Casing provides locations for the installation of blowout preventers wellhead equipment production packers and production tubing.

329 63 PROTECTION OF CASING CORROSION FROM Casing can be protected by one or a combination of the following. Todays steel casings are coated with a polymer making them very smooth as well as corrosion and rust resistant. Corrosion-Resistant Casing L80C90T95 C110 API 5CT steel grades L80-1 C90 T95 and C110 show a higher resistance to sulfide stress cracking in H2S environments due to lower limits of sulfur and phosphorous as well as the addition of the following mandatory tests.

To improve the corrosion resistance for the demanding conditions of particular oil and gas wells TPCO has developed a variety of proprietary steel grades that extend the life span of pipe products reducing corrosion rates. Documented Examples of Pipe Corrosion and Failure. High Yield Steels Specifying higher yield strength steel in lieu of a mild steel piling grade is another method to counter potential corrosion losses over the life of the project.

Corrosive ammo is a bit of a misnomer as the ammo itself is not corrosive however the primers in this ammo contain a priming compound that utilizes corrosive salts. However the selection of casing for a. WELL CASING STEEL OR PLASTICThis article written by the American Ground Water Trust was originally published in THE AMERICAN WELL OWNER 2003 Number 4WELL CASING STEEL OR PLASTICIn the grocery store we are often asked paper or plastic We have a choice based on convenience and our perception of recycling benefits.

Buried pipe Soil side and fluid side Carbon steel and stainless steel materials Use results to improve inspection guidance to plants. N-80 actually might be a down-rated P-110 but L-80 cannot be. Grade The steel grade of the casing relates to the tensile strength of the steel from which the casing is made.

After further inspection the well head. If you reload you will likely discover that using Boxer-primed casing is far more convenient and accessible than Berdan. Steel is used for casing because it is strong enough not to break if the ground or rocks shift a bit or when working deeper than the limits of PVC casing.

The appropriate casing grade for any application typically is based on pressure and corrosion requirements. Steel Casing Ammo Myths Exposed. C90 API grade.

Exposed Well Casing Corrosion. Generally Stainless Steel casing is so expensive it is preferred to use. People say they rust they jam they corrode your firearms they misfire but these are not true at all.

Since the well designer is concerned about the pipe yielding under. Production casing collapse loads assumes zero pressure on the inside of the pipe and a final mud weight gradient on the outside of the casing. CorrView International LLC offers a series of photo galleries taken from 18 years of past ultrasonic piping investigations which address the above and additional corrosion conditions.

Rated internal yield pressure of casing is calculated using the Barlow Equation below. 9 Cementation placement of. As far as I know there is no corrosion allowance exactly specified in ASME B313.

Hermetically sealed the pile forms a closed air-tight casing and corrosion of the internal surface of the pile becomes negligible. L-80 has a maximum Rockwell hardness value of 22 but N-80 does not. Some operators recommend it be full-length normalized or normalized and tempered after upsetting when used in carbon dioxide or sour service ring-worm corrosion problems.

The casing grade P-110 designates a higher strength pipe with minimum yield strength of 110000 psi 758422 KPa. Both the home inspector and appraiser made note of a well head directly in the back of the house. Increasing the minimum yield.

But PVC casing is used in a lot of areas where the ground doesnt shift. While doing yard work I noticed a second newer well head in a wooded part of the lot. Once fired these corrosive salts will be deposited in the barrel gas system bolt and chamber of your firearm and begin to corrode unless properly and quickly removed.

The outer winding protective film of casing has very high corrosion resistance which requires the ability to resist abrasion when running down resist bite of casing pliers or repair the bite in time on the drilling platform. The steel grade is expressed as a code number which consists of a letter and a number. For example the casing grade J-55 has minimum yield strength of 55000 psi 379211 KPa.

Determine corrosion rates for use in FFS and remaining life evaluations Topical Report that complements Code Case N-806 Scope. From the outer casing shoe to total depth TD the external pressure profile is the pore pressure profile. The letter is arbitrary selected to provide a.

Using outer winding protective film of casing. 15 mm for piping is a common standard but you are free to set a corrosion allowances you wish unless a state or local agency has adopted and. Steel casings are one of the most misunderstood cartridge components out there.

For instance carbon dioxide corrosion of steel at a temperature above 70 C can lead to the formation of a protective iron carbonate scale that can significantly affect the rate and mechanism of corrosion. Corrosion Resistance Casing We provide a complete range of steel grades for all kinds of oil and gas operations. But access to products doesnt tell the whole story.

However such heat treatments. 9 Using wellhead insulator electrical insulation of well casing from the flow- line. Materials for use in H2S-containing environments in oil and gas production issued by the National Association of Corrosion Engineers.

Typically the H 2 S partial pressure should be less than 15 psi for safe use of L80 Type 13 Cr. The grades with the letter designation L and C have maximum hardness limitations and are for specific applications where H2S is present. Consequently the curve sloping to the left from bottom indicates corroding zone anode where electrons are leaving the casing.

17 If a test interval of 3 days is selected for corrosion coupon tests under carbon dioxide corrosion environments it may lead to the reporting of falsely high. I purchased my first house built in 1979 back in July. Those hardness limits are also shown in the table.

All of which would snap off PVC casing.

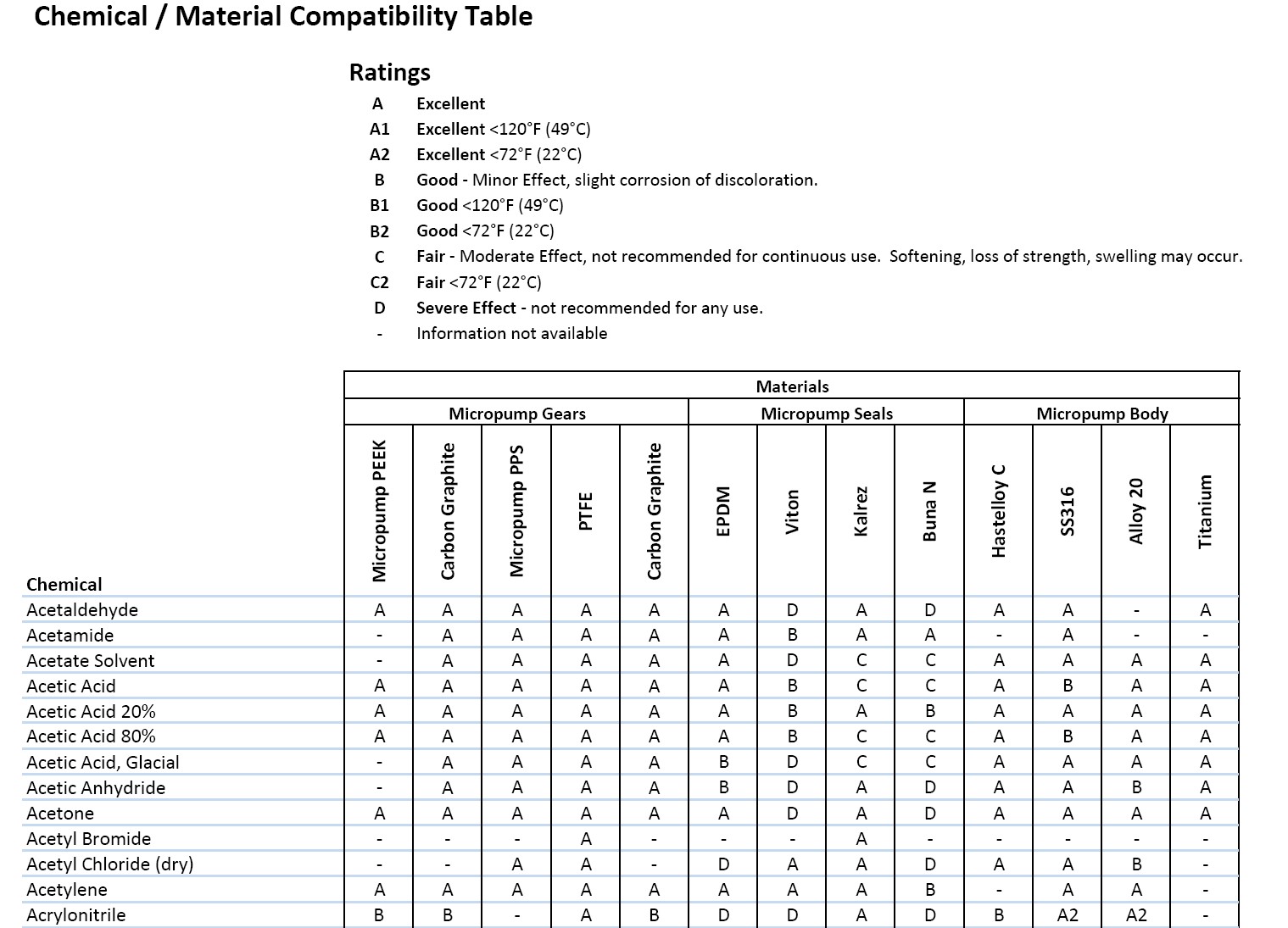

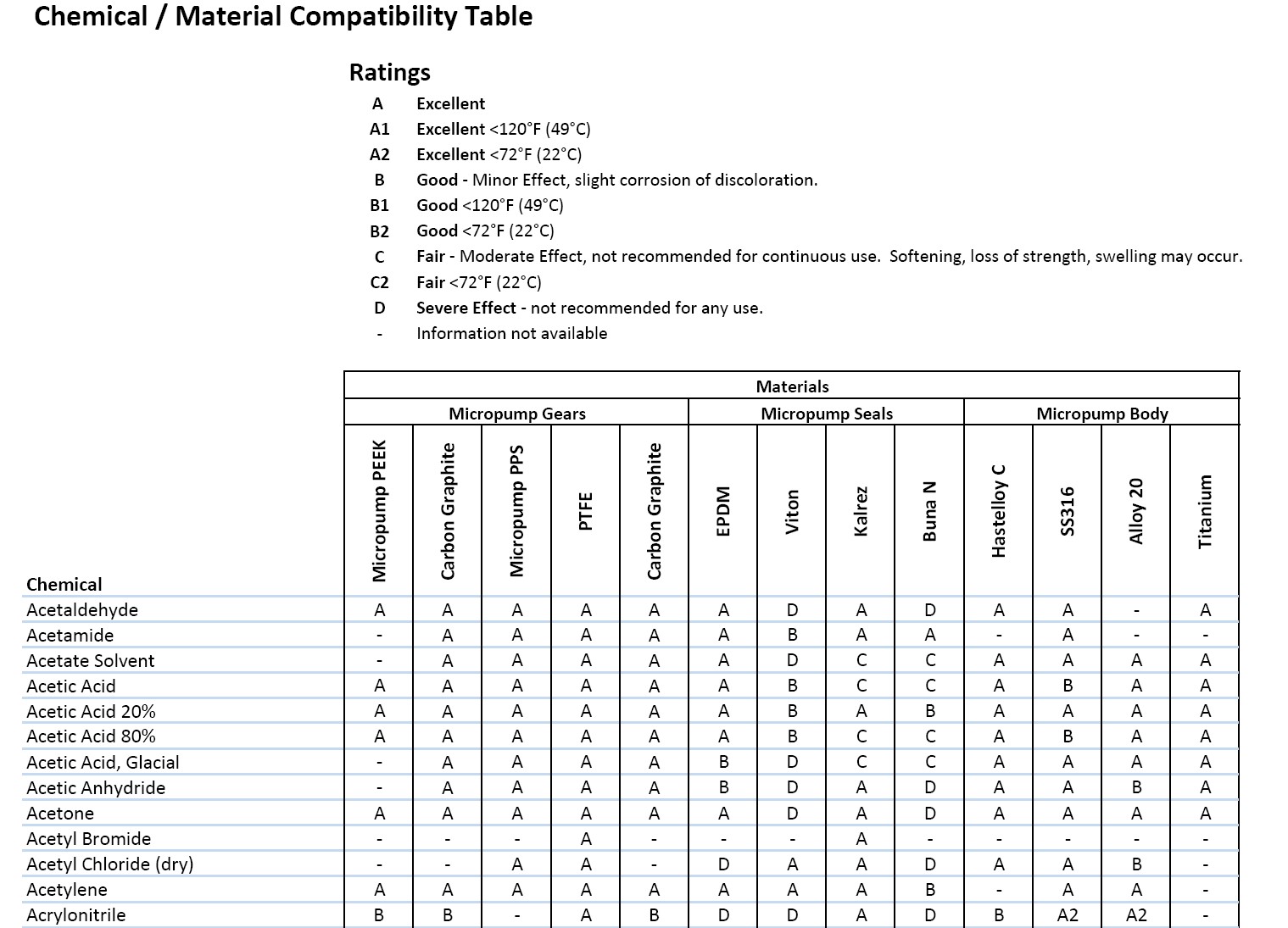

Useful Info On Pump Corrosion Chemical Compatibility

Galvanic Corrosion Behavior Of Dissimilar Casing Steels In High Sulfur Containing Gas Wells Sciencedirect

0 Comments